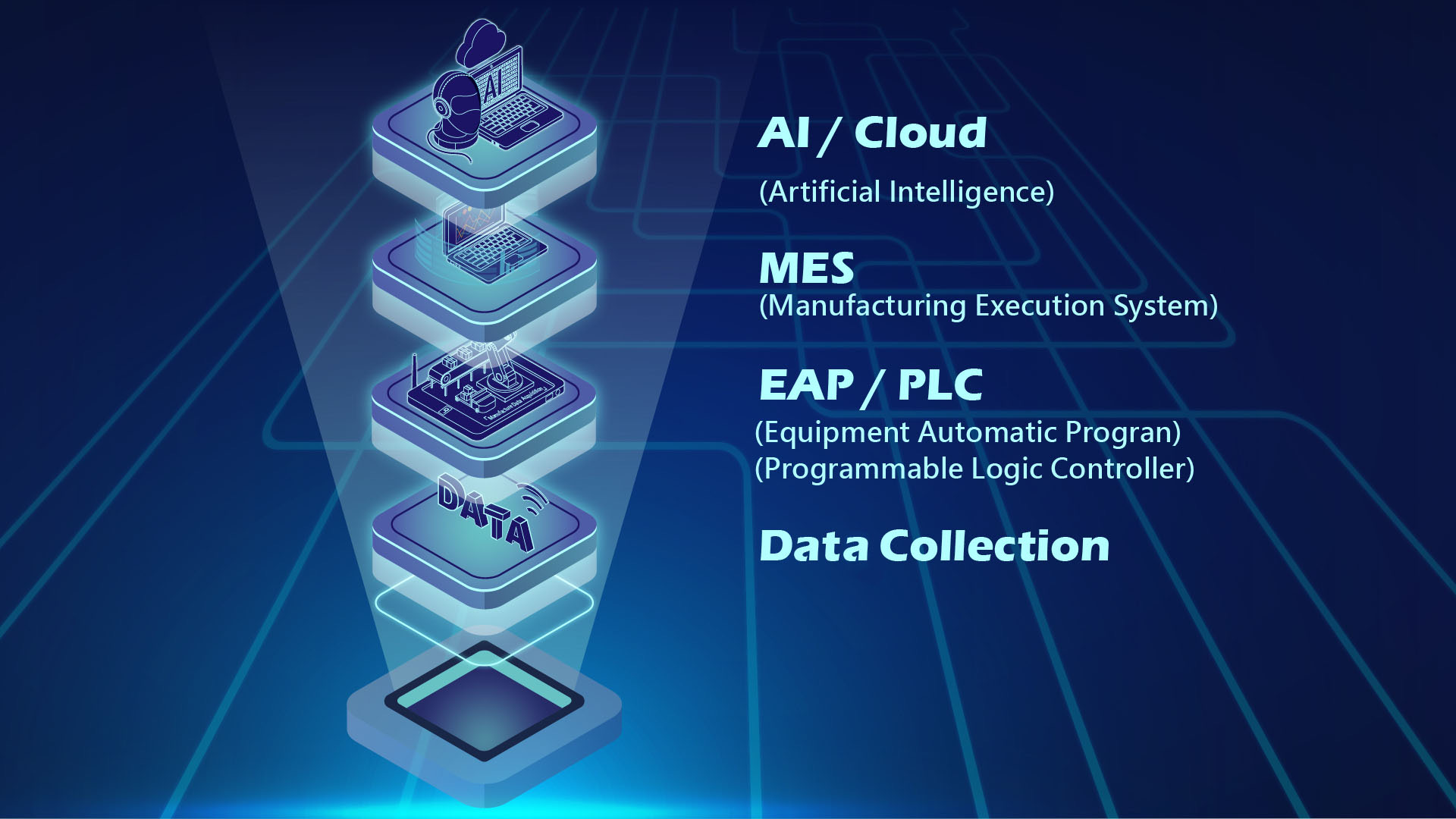

Total Solution of Industry 4.0

• Traceability • WIP Control • PLC Automatic Connection • CIM(Computer-Integrated Manufacturing) • CIM(Computer-Integrated Manufacturing) • EAP(Equipment Automatic Program) • Professional Quality Control System

• SPC(Statistical Process Control) • OCAP(Out of Control Action Plan) • EMS(Equipment Management System) • OEE(Overall equipment effectiveness) • Real Time Production Report • Yield Rate Report